• Adopt MEMS monocrystal silicon high-precision pressure sensor

• With high response speed and stability

• Measurement accuracy 0.2%FS

• The max. range ratio can reach to 10:1

• Adopt double overload protection technology

• Provide standard HART bus communication mode

• Sophisticated self-diagnosis and telecommunication function

• Highlighted LCD with backlight

• Local display screen which can rotate by 360º

• Convenient local zero clearing function

• Convenient local zero point, extreme point setting and calibration function

• Convenient local current loop calibration function

Performance index

The overal performance is the composition error based on the reference accuracy, ambient temperature effects and range static-pressure effects.

Accuracy index

±0.2%FS range (conventional)

Concrete performance index

(Zero-base range, reference conditions, silicone oil filling liquid, 316 stainless steel isolation diaphragm, 4~20mA analog output, the digital fine-tuning value is equal to the set point value of range.)

Accuracy

(The reference accuracy includes hysteresis, linear, setting ability and repeatability, which are based on terminal.)

±0.2%range

If the range is less than X

±[0.025+0.05 ]%

]%

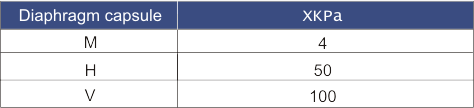

X value:

Damping time constant

The total damping time constant is equal to the sum of the damping time constants of amplifier unit and diaphragm capsule. The damping time constant of amplifier unit is adjustable within the range of 0~100s.

Diaphragm capsule (silicone oil)

Time constant (s) (The time constant can be set according to the actual situation of field and is recommended 1S)

Influence of installation position

The changing of installation position, which is parallel to the surface of diaphragm, will not cause the effect of null shift. If the change between the installation position and the surface of diaphragm do not exceed 90°, the null shift within 0.4KPa can be corrected by zero setting without influencing the range.

Influence of power supply

Less than ±0.005% range/v

Functional parameter

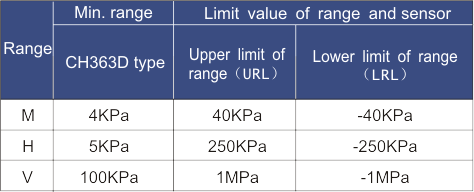

The limit value of range and sensor

Table 1: Range of 363L transmitter and limit value of sensor

Zero point and range adjustment requirements

·The zero point and range can be adjusted arbitrarily within the range limit value indicated in Table 1.

·The range should be larger than or equal to the min. range indicated in Table 1.

Applications

Measurement of liquid, gas and steam

Output

Two-wire 4-20mA, linear output or square root output is selectable for users. Digital process variable overlays on

the 4-20mA signal, which can be applied to the host machines according with HART protocol.

Power supply

Need external power supply. While standard transmitter (4-20mA) has no load, work at 14.5-45V DC.

Loop load limit

The max. loop resistance is decided by the voltage of external power supply, the relations are as follows:

Note: The supply voltage range of transmitter with backlight display is 14.5~45V

The supply voltage range of intrinsic-safety series transmitter is 14.5~28V.

The working voltage while HART communication should be larger than 17.5V.

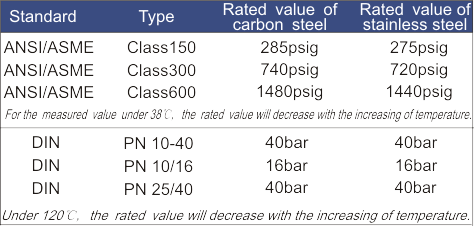

Limit of static pressure and max. overpressure

For 363D type, the limit value is from 0psia to flange rated

value or the smaller one in the rated pressure values of sensor.

Table 2. Pressure rated value of 363G type flange

Fault mode

Output code

While discovering the faults of sensor or microprocessor by self diagnosis, the transmitter will output one high or

low alarm signal to prompt the users. The alarm output value is subject to the factory configuration mode of transmitter:

Linear output: 3.8<I<20.8

C4: I=20.8mA high fault

CN: I=3.8mA low fault

Temperature limit

Environment

-20℃~+70℃ (Ordinary)

-40℃~+85℃ (The highest)

Storage

-46℃~110℃

With header: -40℃~85℃

Process

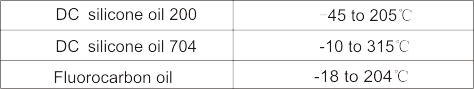

Less than or equal to atmosphere, see the following table:

Table 3. Limit of 363D process temperature

Humidity limit

0-100% relative humidity

Starting time

Reach to the performance index within 2s after the transmitter is power up.

Mechanical performance index

Electrical interface

ANSI (American-Standrad) NPT1/2(F) internal thread

ISO (Chinese standard) M20×1.5 internal thread

Process interface

High-pressure side: flange size (execute national and chemical industry standard)

NP series: DN25 DN40 DN50 DN80 DN100

PN2.5 PN6 PN10 PN16 PN25 PN40

Class series: 1 inch, 1½ inches, 2inches, 3inches,

4 inches, 150lb、300lb

Low-pressure side: flange size (execute national and chemical industry standard)

NP series: DN25 DN40 DN50 DN80 DN100

PN2.5 PN6 PN10 PN16 PN25 PN40

Class series: 1 inch, 1½ inches, 2inches, 3inches,

4 inches, 150lb、300lb

Process liquid-contacting piece

Process isolation diaphragm: 316L stainless steel, hastelloy C (Plug-in cartridge doesn’t have this option.),

Ta (Plug-in cartridge doesn’t have this option.).

Drain/vent valve

316 stainless steel

Process flange and interface

316 stainless steel

363G type process liquid-contacting piece

Flange type process interface (the high-pressure side of transmitter)

Process diaphragm, including process gasket contacting surface

316L stainless steel, hastelloy C or Ta

Extension part

316 stainless steel

Mounting flange

Carbon steel galvanization or stainless steel

Process connection on the low-pressure side (the low-pressure side of transmitter)

Isolation diaphragm

316L stainless steel

Flange and interface on the low-pressure side

316 stainless steel

Non-liquid-contacting piece

Shell

Aluminium die casting IP65

Coating

Spraying plastics

Meter cap O-ring

Nitrile rubber